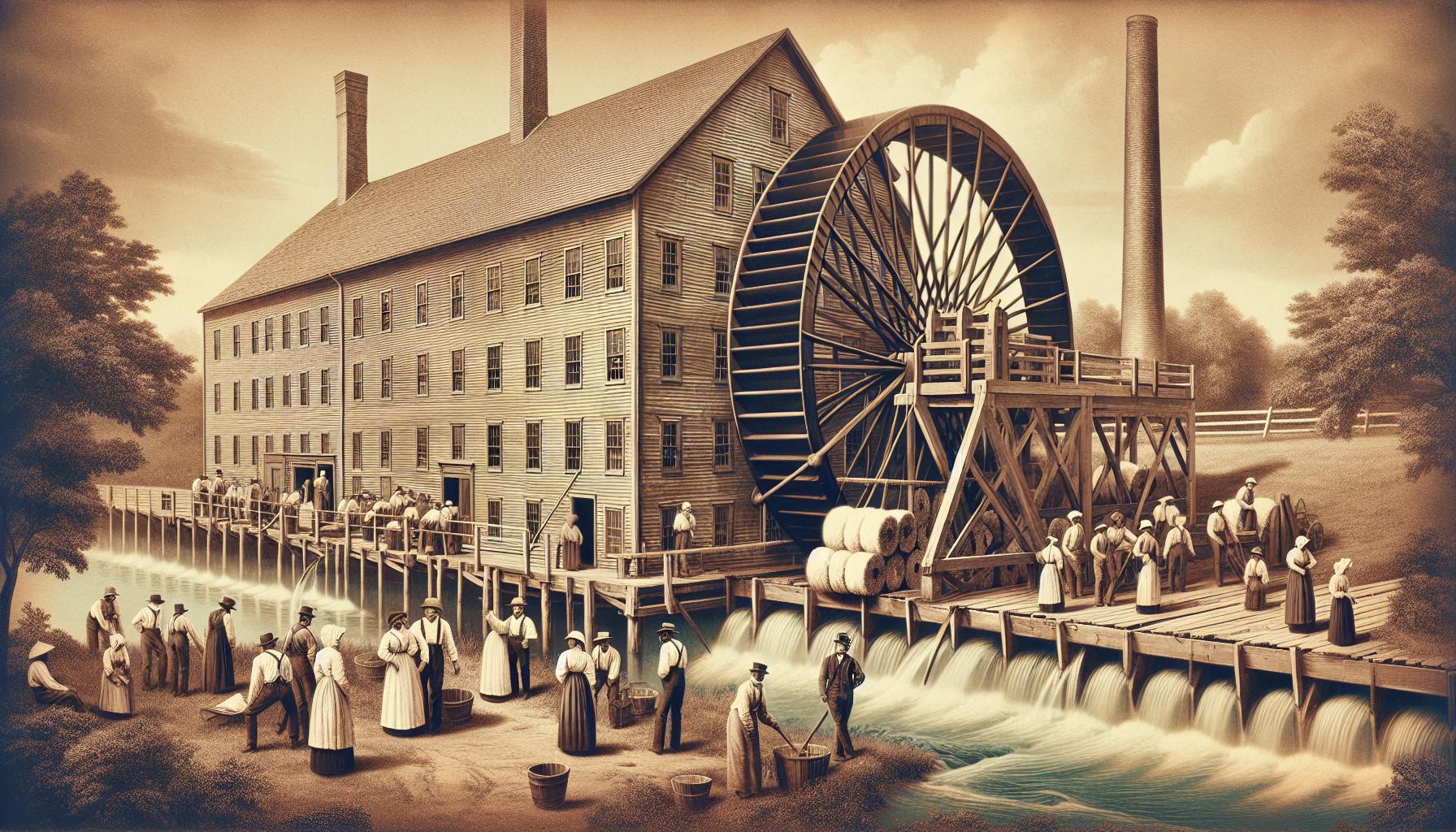

Samuel Slater establishes the first water-powered cotton spinning mill in Pawtucket, Rhode Island, marking the beginning of the American Industrial Revolution and transforming the nation's manufacturing landscape.

The birth of America's industrial revolution can be traced back to 1790 when Samuel Slater established the first water-powered cotton spinning mill in Pawtucket Rhode Island. This groundbreaking facility known as Slater Mill marked the beginning of the American factory system and transformed the nation's manufacturing landscape.

After memorizing the designs of English textile machines Slater brought this valuable knowledge to America where he partnered with Moses Brown to create a revolutionary manufacturing facility. The success of Slater Mill sparked rapid industrialization throughout New England leading to the emergence of numerous factories and mill towns. This innovative venture earned Samuel Slater the nickname "Father of the American Industrial Revolution" from President Andrew Jackson and established Rhode Island as a pivotal location in American manufacturing history.

Samuel Slater's Revolutionary Vision

#Samuel Slater's expertise in textile manufacturing sparked a transformative industrial movement in America. At age 21, Slater arrived in New York in 1789 with detailed mental blueprints of English spinning machinery designs stored in his memory. The British laws prohibited the export of textile machinery designs, making Slater's memorized knowledge invaluable.

Moses Brown, a prominent Rhode Island merchant, partnered with Slater in 1790 after learning of his textile expertise. Brown provided the capital investment while Slater contributed his technical knowledge to establish the mill. Their partnership revolutionized American manufacturing through three key innovations:

- Implementing water-powered machinery for cotton spinning

- Creating a structured factory labor system

- Developing standardized production methods

The Slater Mill system incorporated specific operational features:

- Organized workflow patterns

- Specialized worker roles

- Quality control measures

- Efficient production schedules

- Systematic maintenance procedures

| Slater Mill Production Statistics (1790-1800) | |

|---|---|

| Initial Workers | 9 |

| Production Capacity | 400 spindles |

| Daily Output | 40 lbs of yarn |

| Operating Hours | 12-14 hours/day |

| Child Workers Age Range | 7-12 years |

Slater's manufacturing model attracted entrepreneurs nationwide who sought to replicate his success. By 1815, 165 mills operated across New England using Slater's system, demonstrating the scalability of his industrial vision. This rapid expansion established Rhode Island as America's earliest industrial center, with Pawtucket serving as the blueprint for future manufacturing communities.

The Birth of Slater Mill in 1793

#Slater Mill officially commenced operations in December 1793, establishing America's first successful water-powered cotton spinning mill in Pawtucket, Rhode Island. The mill's completion marked a pivotal moment in American manufacturing history, transforming domestic production methods.

Construction and Early Operations

#The construction of Slater Mill began in 1793 on the banks of the Blackstone River. Moses Brown invested $250 in the initial construction phase, creating a 29-foot by 43-foot wooden structure powered by a water wheel system. The mill featured:

- Spinning frames with 72 spindles

- Three floors of operational space

- A basement level for mechanical components

- Water-powered machinery driven by a 7-foot diameter wheel

| Construction Details | Specifications |

|---|---|

| Building Size | 29' x 43' |

| Number of Floors | 3 + basement |

| Initial Investment | $250 |

| Water Wheel Size | 7' diameter |

| Spindle Capacity | 72 spindles |

British Technology Meets American Industry

#Slater's mill integrated British technological innovations with local materials and labor practices. Key technological implementations included:

-

Card machines for cotton preparation

-

Water frame spinning technology

-

Frame stands adapted for water power

-

Modified Arkwright system components

-

American-made wooden machine parts

-

Employed local craftsmen for machine construction

-

Modified British designs for American materials

-

Integrated water power mechanisms with spinning operations

-

Established standardized production methods

-

Created specialized worker training programs

Impact on Rhode Island's Economy

#The establishment of Slater Mill transformed Rhode Island's economic landscape from an agricultural-based economy to an industrial powerhouse. This transformation created lasting effects that shaped the state's development for generations.

Creating the American Factory System

#Slater Mill's operational model generated substantial economic growth in Rhode Island through systematic manufacturing processes. The factory employed 100 workers by 1800, establishing standardized wages for skilled labor. Local merchants experienced increased business activity, supplying raw materials to the mill while distributing finished textile products. The success of this system attracted $2.7 million in industrial investment to Rhode Island between 1790-1815, leading to the establishment of 45 textile mills in the state.

- Enhanced transportation infrastructure with 150 miles of improved roads by 1820

- Development of specialized banking systems supporting industrial growth

- Creation of auxiliary industries: machine shops, foundries, tool manufacturers

- Establishment of technical training programs for skilled workers

- Formation of merchant networks connecting Rhode Island products to national markets

| Economic Indicator | 1790 | 1815 |

|---|---|---|

| Manufacturing Jobs | 850 | 12,000 |

| Active Mills | 1 | 45 |

| Industrial Investment | $250 | $2.7M |

| Miles of Improved Roads | 15 | 150 |

Life in Early Factory Communities

#Early factory communities in Rhode Island centered around textile mills transformed social structures through organized labor systems industrial housing patterns. The emergence of these manufacturing hubs created distinct cultural identities that shaped American industrial society.

Working Conditions and Labor Practices

#Factory work in early Rhode Island mills followed strict schedules with 12-14 hour workdays starting at sunrise. Workers operated in three-story wooden buildings with limited ventilation filled with cotton dust wool fibers. The workforce consisted primarily of families including:

- Women earned $2-4 weekly operating spinning frames looms

- Children aged 7-12 received 33-50 cents weekly as bobbin boys cleaners

- Men earned $4-10 weekly maintaining machinery supervising operations

Safety measures remained minimal with:

- No protective equipment for machinery operation

- Limited lighting from small windows oil lamps

- Cramped spaces between equipment rows

- Exposure to loud mechanical noise cotton particles

Formation of Mill Villages

#Mill villages emerged as self-contained communities designed to support factory operations efficiency. These planned settlements included:

Housing Infrastructure:

- Company-owned tenements housing 4-6 families each

- Single-family cottages for skilled workers supervisors

- Boarding houses for unmarried workers

Community Facilities:

- Company stores providing food supplies

- Schools teaching basic education practical skills

- Churches serving as social gathering centers

- Markets gardens for food production

The mill village system established social hierarchies based on:

- Job positions within the factory

- Housing location quality

- Access to community resources

- Family involvement in mill operations

| Village Name | Year Established | Peak Population | Number of Mills |

|---|---|---|---|

| Slatersville | 1803 | 3,000 | 4 |

| Lonsdale | 1831 | 2,500 | 3 |

| Ashton | 1867 | 1,800 | 2 |

Legacy of America's First Factory

#Slater Mill's enduring impact on American industry extends far beyond its operational years. The site's preservation honors its pivotal role in launching the American Industrial Revolution while influencing modern manufacturing practices.

Preservation as a Historic Landmark

#The Slater Mill Historic Site earned National Historic Landmark status in 1966, recognizing its significance in American industrial heritage. The preserved complex includes three historic buildings: the original 1793 mill, the 1810 Wilkinson Mill, and the 1758 Sylvanus Brown House. The Old Slater Mill Association maintains the site as a living museum, offering educational programs and guided tours to 50,000 annual visitors. The restoration project completed in 1925 accurately depicts the original manufacturing processes through preserved machinery, tools, and artifacts.

Influence on Modern Manufacturing

#Slater Mill established fundamental manufacturing principles that continue to shape contemporary industrial practices. The site introduced:

| Manufacturing Innovation | Impact on Modern Industry |

|---|---|

| Assembly Line Layout | Standardized production flow systems |

| Quality Control Methods | Modern quality assurance protocols |

| Worker Specialization | Current job classification systems |

| Systematic Maintenance | Preventive maintenance programs |

| Production Scheduling | Just-in-time manufacturing |

The factory's water-powered technology evolved into sustainable energy practices, with 15% of modern U.S. manufacturing facilities utilizing hydroelectric power. Manufacturing centers continue to implement Slater's organizational framework, including specialized worker training programs, efficient workflow patterns, and systematic quality control measures.

Key Takeaways

#- The first American factory, Slater Mill, was established in 1790 in Pawtucket, Rhode Island by Samuel Slater and Moses Brown

- Samuel Slater earned the title "Father of the American Industrial Revolution" by memorizing British textile machinery designs and implementing them in America

- The mill began operations in December 1793 with a $250 investment, featuring 72 spindles across 3 floors and a water-powered system

- By 1815, Slater's manufacturing model inspired 165 mills across New England, transforming Rhode Island into America's earliest industrial center

- The factory system created mill villages and new social structures, with 12-14 hour workdays and a workforce including women, children, and men

- Today, Slater Mill is a National Historic Landmark (since 1966) receiving 50,000 annual visitors and showcasing America's industrial heritage

Conclusion

#Rhode Island's Slater Mill stands as a testament to American industrial ingenuity and innovation. This pioneering facility not only launched the nation's manufacturing revolution but also established foundational principles that continue to shape modern industry.

Today the preserved site serves as a powerful reminder of America's transition from an agricultural to an industrial economy. The legacy of Samuel Slater's vision extends far beyond the physical structure demonstrating how a single factory in Pawtucket transformed manufacturing practices nationwide.

Slater Mill remains a symbol of American entrepreneurship and technological advancement welcoming visitors who seek to understand the roots of U.S. industrial heritage. Its influence on manufacturing standards quality control and labor practices has created an enduring impact that resonates throughout contemporary American industry.