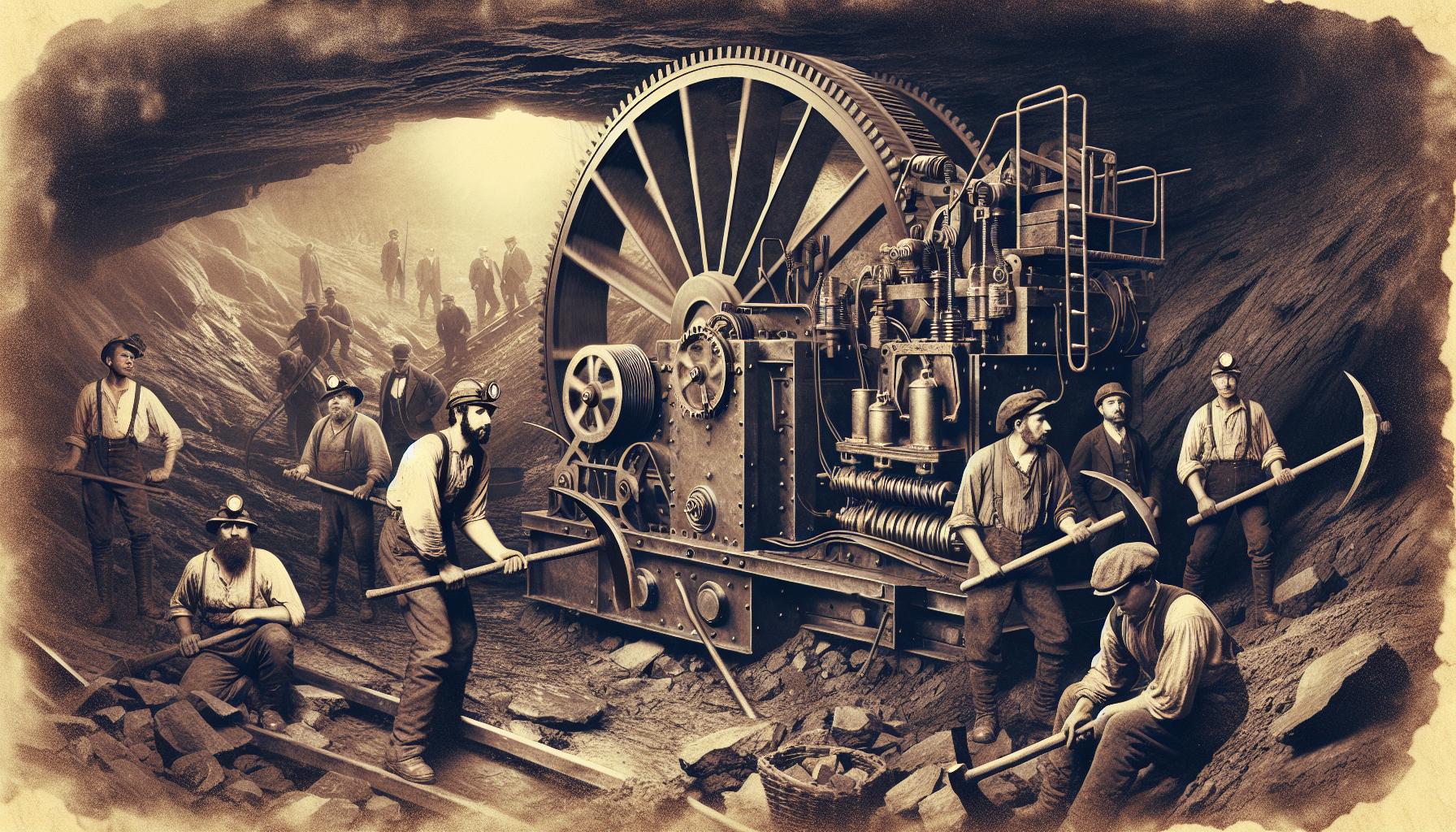

The transformation of coal mining from manual labor to mechanized processes, marking a revolutionary change in industrial history through technological innovations from the 1800s onwards.

The evolution of coal mining machinery marks a pivotal moment in industrial history, transforming what was once backbreaking manual labor into a mechanized process. The first significant coal mining machines emerged in the early 1800s, revolutionizing an industry that had relied primarily on pickaxes and human strength for centuries.

The introduction of steam-powered engines in British coal mines during the Industrial Revolution set the stage for modern mining equipment. These early innovations, including primitive coal cutters and basic hauling systems, laid the groundwork for the sophisticated machinery used today. While these initial machines were crude by modern standards they represented a crucial step forward in mining technology and workplace safety.

The Early Days of Manual Coal Mining

#Manual coal mining dominated the industry from ancient times through the late 18th century. Miners used basic hand tools like picks axes hammers chisels to extract coal from shallow surface deposits underground seams.

The primary mining methods included:

- Drift mining through horizontal tunnels into hillsides

- Bell pit mining in circular holes up to 40 feet deep

- Shaft mining straight down to reach deeper coal seams

- Room pillar mining leaving coal pillars to support the roof

Mining tools consisted of:

- Iron picks for breaking coal from the seam

- Shovels baskets for collecting loose coal

- Oil lamps candles for underground illumination

- Wooden props timbers for roof support

Miners faced hazardous conditions including:

- Toxic gases methane carbon monoxide

- Cave-ins roof collapses

- Flooding underground water seepage

- Limited ventilation poor air quality

Transportation methods relied on:

- Human haulers carrying baskets on their backs

- Child workers dragging coal sleds through tunnels

- Horse-drawn carts on wooden rails

- Manual winches for lifting coal up shafts

| Mining Activity | Manual Method | Daily Output per Miner |

|---|---|---|

| Coal Extraction | Pick Axe | 0.5-1 ton |

| Underground Transport | Hand Cart | 0.3-0.5 ton |

| Surface Transport | Horse Cart | 1-2 tons |

| Shaft Lifting | Hand Winch | 0.2-0.4 ton |

These labor-intensive methods defined coal mining for centuries until the emergence of mechanical innovations in the early 1800s transformed the industry's capabilities productivity.

The Industrial Revolution's Impact on Mining

#The Industrial Revolution marked a transformative period in mining mechanization from 1760 to 1840. This era introduced revolutionary coal extraction technology that reshaped mining operations through steam power innovation.

Steam-Powered Engines Transform Mining

#Steam engines revolutionized mining operations by powering essential machinery for coal extraction. The introduction of steam-powered hoisting engines in 1780 enabled miners to lift heavier loads from deeper mine shafts efficiently. These engines replaced horse-powered gins, increasing daily coal production from 10 tons to 100 tons per shaft.

Key advancements in steam-powered mining equipment:

- Mechanical ventilation fans improved air circulation in mine shafts

- Steam-driven rope haulage systems transported coal underground

- Mechanical coal cutting machines reduced manual labor requirements

- Steam-powered pumps drained water from mine shafts

Introduction of the Steam Pump (1712)

#Thomas Newcomen's atmospheric steam pump in 1712 marked the first significant mining equipment advancement. The pump removed groundwater from mine shafts at a rate of 500 gallons per minute, enabling access to deeper coal seams.

| Improvement | Before Steam Pump | After Steam Pump |

|---|---|---|

| Mining Depth | 150 feet | 300+ feet |

| Water Removal | 50 gal/min | 500 gal/min |

| Active Mine Life | 5-10 years | 20+ years |

| Coal Production | 100 tons/month | 500 tons/month |

First Mechanical Coal Cutters

#Mechanical coal cutters revolutionized mining operations by replacing manual labor with powered machinery. These innovations marked a crucial shift in coal extraction technology during the Industrial Revolution.

The Pick Machine (1761)

#The pick machine emerged as the first mechanical coal cutter in 1761, developed by Michael Menzies at Newcastle-upon-Tyne. This pioneering device featured a rotating wheel equipped with steel picks, mounted on a mobile frame. The machine operated by:

- Utilizing mechanical power to drive picks into coal seams

- Moving along rails positioned at the coal face

- Cutting horizontal grooves at the base of coal walls

- Producing 30% more coal compared to manual methods

| Pick Machine Statistics | |

|---|---|

| Year Introduced | 1761 |

| Production Increase | 30% |

| Operating Location | Coal face |

| Power Source | Manual wheel mechanism |

The Havelock Mechanical Coal Cutter (1862)

#The Havelock coal cutter represented a significant advancement in mining mechanization. Created by James Havelock, this machine incorporated:

-

Steam-powered cutting mechanisms

-

Chain-driven cutting bars

-

Automatic feed systems

-

Mobile undercarriage for improved maneuverability

-

40% reduction in manual labor requirements

-

Increased mining depth capabilities

-

Enhanced worker safety conditions

-

Standardized cutting depths

| Havelock Cutter Performance | |

|---|---|

| Cutting Speed | 12 ft/hour |

| Labor Reduction | 40% |

| Year Introduced | 1862 |

| Power Source | Steam engine |

Evolution of Mining Transportation

#Mining transportation systems evolved significantly from basic manual methods to sophisticated mechanical solutions, transforming the efficiency of coal extraction operations. This evolution paralleled the broader mechanization of the mining industry.

Early Rail Systems and Coal Carts

#The first rail systems in coal mines emerged in the 1820s, featuring wooden tracks that supported horse-drawn coal carts. These primitive railways evolved into cast iron rail tracks by 1830, enabling the movement of heavier loads with less friction. The introduction of steam locomotives in mines during the 1840s increased hauling capacity from 20 tons to 200 tons per trip.

Key developments in early rail transportation:

- Cast iron plateways replaced wooden tracks in 1825

- Flanged wheels improved cart stability in 1832

- Steam-powered hoisting engines lifted coal from deeper levels

- Underground rope haulage systems transported coal along horizontal tunnels

Mechanical Conveyor Systems

#Mechanical conveyors revolutionized coal transportation in mines during the 1890s, marking a significant advancement in mining mechanization. The first successful underground conveyor belt, installed in 1895, transported 50 tons of coal per hour compared to traditional cart systems that moved only 10 tons.

- Chain conveyors introduced in 1897 for steep inclines

- Rubber belt conveyors implemented in 1905 for longer distances

- Shaker conveyors developed in 1910 for low-ceiling areas

- Pan conveyors designed in 1920 for heavy-duty operations

| Transportation Method | Year Introduced | Capacity (tons/hour) |

|---|---|---|

| Horse-drawn carts | 1820 | 2-3 |

| Steam locomotives | 1840 | 25-30 |

| Chain conveyors | 1897 | 35-40 |

| Rubber belt systems | 1905 | 50-60 |

Modern Mechanization Era

#Mining mechanization entered a transformative phase in the early 20th century with the introduction of electric power systems in mines. This shift marked the beginning of modern coal extraction technology characterized by increased efficiency automated systems.

Electric-Powered Mining Equipment

#The first electric-powered mining equipment appeared in American coal mines in 1889, featuring direct current motors for coal cutters. Electric cutting machines increased production rates to 150 tons per shift compared to 50 tons with steam-powered equipment. By 1920, alternating current systems powered essential mining equipment:

-

Electric locomotives capable of hauling 200 tons of coal per trip

-

Electrically-driven ventilation fans processing 500,000 cubic feet of air per minute

-

Battery-operated drilling machines completing 40 holes per shift

-

Electric hoisting systems lifting 10 tons of coal in a single load

-

Cutting mechanisms removing 5 tons of coal per minute

-

Built-in gathering arms collecting loose coal

-

Integrated conveyor systems moving coal to transport vehicles

-

Self-propelled chassis allowing rapid repositioning

| Continuous Miner Advancement | Year | Production Rate |

|---|---|---|

| First Joy Continuous Miner | 1948 | 300 tons/shift |

| Remote Control Models | 1960 | 600 tons/shift |

| Computer-Guided Systems | 1975 | 1,200 tons/shift |

| Modern Smart Miners | 2000 | 2,000 tons/shift |

Key Takeaways

#- The first significant coal mining machines emerged in the early 1800s, marking a transition from manual labor during the Industrial Revolution

- Thomas Newcomen's atmospheric steam pump (1712) was the first major mining innovation, enabling water removal at 500 gallons per minute and deeper mining operations

- The first mechanical coal cutter, the Pick Machine, was developed in 1761 by Michael Menzies, increasing production by 30% compared to manual methods

- Transportation systems evolved from basic horse-drawn carts in the 1820s to steam locomotives in the 1840s, increasing hauling capacity from 20 to 200 tons per trip

- Electric-powered mining equipment was introduced in 1889, revolutionizing production rates from 50 to 150 tons per shift compared to steam-powered equipment

- The continuous miner, introduced in 1948, represented a major advancement in automation, capable of removing, gathering, and transporting coal simultaneously

Conclusion

#The introduction of coal mining machinery represents a pivotal moment in industrial history. From the first steam-powered engines in the early 1800s to modern automated systems the evolution of mining equipment has transformed how we extract coal. These technological advancements didn't just boost productivity - they revolutionized workplace safety and efficiency.

Today's sophisticated mining operations stand as a testament to over two centuries of innovation. The progression from basic mechanical tools to smart continuous miners showcases humanity's drive to improve and innovate. This technological evolution continues to shape the future of coal mining while making the industry safer and more efficient than ever before.