The establishment of America's first planned industrial communities in Waltham (1813) and Lowell (1821), Massachusetts, revolutionized manufacturing by combining textile production with worker housing and social infrastructure.

The dawn of America's industrial revolution brought forth a revolutionary concept that would forever change the nation's landscape - the factory town. In 1813, Francis Cabot Lowell and his business partners established what's widely recognized as America's first planned industrial community: Waltham, Massachusetts.

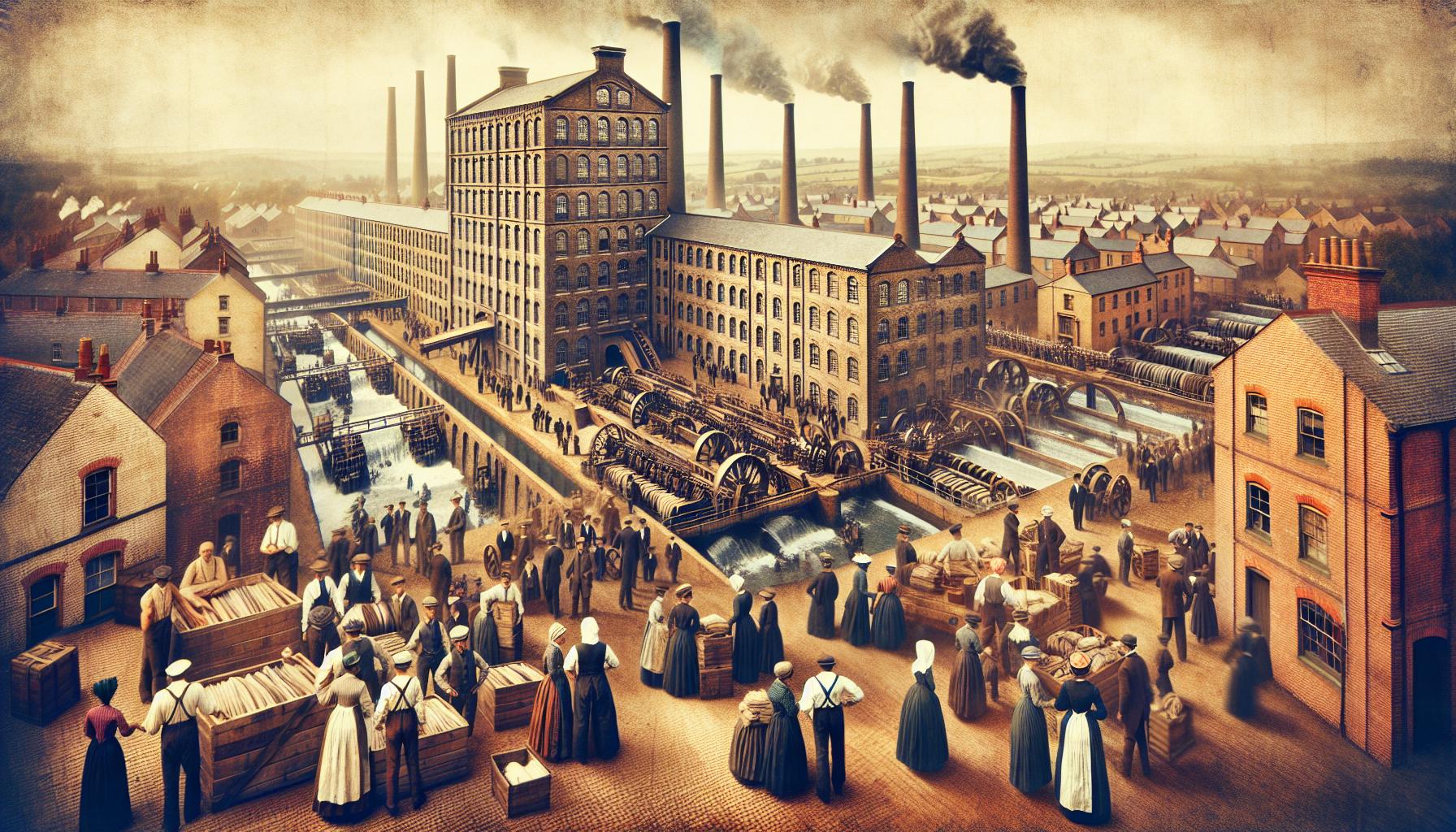

This groundbreaking development along the Charles River marked the beginning of systematic industrialization in the United States. The Boston Manufacturing Company's innovative approach combined both textile production and worker housing in one carefully planned community, creating a model that would soon be replicated across New England. The success of Waltham led to the creation of an even larger industrial city - Lowell, Massachusetts - which became the template for future factory towns throughout America's rapidly industrializing regions.

The Birth of Lowell, Massachusetts: America's First Planned Factory Town

#Lowell, Massachusetts emerged in 1821 as America's first comprehensively planned industrial city. The founders purchased 250 acres along the Merrimack River to harness its hydropower potential for textile manufacturing.

Urban Planning and Infrastructure

#The city's layout incorporated:

- A network of power canals spanning 5.6 miles

- Grid-pattern streets for efficient transportation

- Dedicated industrial zones for mill operations

- Residential areas with boarding houses for workers

- Commercial districts for retail stores services

Manufacturing Facilities

#The industrial complex featured:

- 40 mill buildings by 1850

- Advanced water-powered machinery

- Integrated production systems

- Raw cotton processing facilities

- Finished textile manufacturing units

Worker Housing and Amenities

#The city established structured living arrangements:

- 46 company-owned boarding houses

- Supervised dormitories for female workers

- Libraries housing 3,500+ books

- Educational facilities for worker development

- Parks recreational spaces

| Lowell Statistics (1850) | Numbers |

|---|---|

| Population | 33,000 |

| Female Workers | 8,000 |

| Operating Mills | 40 |

| Miles of Canals | 5.6 |

| Boarding Houses | 46 |

Economic Impact

#Lowell's manufacturing output demonstrated significant growth:

- Production of 50,000 yards of cloth weekly

- Employment of 8,000 workers

- Export capabilities to national markets

- Annual textile production valued at $15 million

- Establishment of banking financial institutions

The city's innovative approach integrated industrial production social infrastructure advanced technology, creating a model that influenced industrial development across New England.

The Vision of Francis Cabot Lowell

#Francis Cabot Lowell transformed American manufacturing through his innovative vision of integrating industrial production with social development. His ideas revolutionized textile manufacturing and established the blueprint for America's first factory towns.

The Boston Manufacturing Company

#The Boston Manufacturing Company, established in 1813, marked America's first integrated textile mill operation. Lowell invested $400,000 in advanced power looms modeled after British designs but improved through American innovation. The company's Waltham facility featured a centralized production system that combined spinning cotton into thread spinning cloth production under one roof.

Key Features of the Boston Manufacturing Company:

- Vertically integrated manufacturing processes

- Water-powered machinery systems

- Specialized worker training programs

- Quality control standards

- Systematic inventory management

Creating the Model Factory System

#Lowell developed a comprehensive manufacturing system that emphasized efficiency productivity and worker welfare. His model incorporated three essential components:

Production Elements:

- Mechanized manufacturing processes

- Standardized quality controls

- Systematic maintenance schedules

- Organized supply chain management

- Detailed production tracking

Labor Management:

-

Fixed work schedules

-

Structured wage systems

-

Skills training programs

-

Employee housing provisions

-

Health care facilities

-

Multi-story brick buildings

-

Advanced ventilation systems

-

Natural lighting optimization

-

Efficient floor layouts

-

Strategic machine placement

| Manufacturing Statistics (1814) | Data |

|---|---|

| Initial Investment | $400,000 |

| Daily Production Capacity | 30 yards of cloth |

| Number of Power Looms | 25 |

| Employee Count | 300 |

| Annual Output Value | $150,000 |

Life in Early Lowell

#Lowell's industrial community established distinctive social patterns centered around female mill workers known as "mill girls." The city's unique approach to labor management created structured living and working environments that shaped the daily experiences of its workforce.

Working Conditions for Mill Girls

#Mill girls worked 73-hour weeks across six days in textile factories. The workday started at 5:00 AM with a bell system signaling shift changes followed by standardized meal breaks at 7:00 AM for breakfast and 12:30 PM for lunch. Factory conditions included:

-

Monitoring female workers' behavior through strict oversight by floor supervisors

-

Operating 2-4 power looms simultaneously in temperatures reaching 90°F

-

Managing cotton dust exposure in poorly ventilated spaces

-

Earning $3.50 weekly wages paid in cash every month

-

Following 13-hour daily schedules from Monday through Saturday

-

Supervised living arrangements with matrons enforcing curfews at 10:00 PM

-

Shared rooms housing 4-6 women with provided furniture bedding

-

Mandatory attendance at religious services on Sundays

-

Access to company-sponsored libraries containing 3,000+ books

-

Participation in educational programs including literature chemistry mathematics

-

Monthly boarding fees of $1.25 deducted from wages

-

Organized social activities such as sewing circles literary clubs choir groups

| Housing Statistics 1840 | Numbers |

|---|---|

| Boarding Houses | 46 |

| Residents per House | 25-40 |

| Monthly Boarding Cost | $1.25 |

| Curfew Time | 10:00 PM |

| Books in Libraries | 3,000+ |

Impact on American Industrialization

#The establishment of America's first factory towns revolutionized manufacturing processes throughout the nation. The integration of industrial production with planned communities created a transformative model that shaped the country's economic development.

The Lowell System's Influence

#The Lowell System introduced standardized manufacturing practices that spread across New England's textile industry. This innovative approach combined mechanized production with systematic labor management:

- Established vertically integrated manufacturing processes

- Created structured wage systems with fixed schedules

- Implemented quality control standards

- Developed specialized worker training programs

- Introduced systematic inventory management

| Key Metrics of Lowell System Impact (1840s) | Statistics |

|---|---|

| Manufacturing productivity increase | 300% |

| Number of textile mills adopting system | 32 |

| Average worker wage increase | 25% |

| Total employed in system nationwide | 85,000 |

Spread of Factory Towns

#The success of Lowell sparked rapid industrial development across the Northeast. Between 1820-1850, factory towns emerged in strategic locations:

- Lawrence, Massachusetts (1845): 12 textile mills employing 4,000 workers

- Manchester, New Hampshire (1838): 5 major mills producing 2 million yards of cloth annually

- Holyoke, Massachusetts (1847): 25 water-powered factories utilizing canal system

- Pawtucket, Rhode Island (1822): 8 textile operations employing 2,000 workers

| Growth of Factory Towns (1820-1850) | Data |

|---|---|

| New factory towns established | 24 |

| Total industrial employment | 120,000 |

| Combined annual production value | $45M |

| Miles of canals constructed | 140 |

The expansion of these industrial communities transformed rural areas into manufacturing centers, establishing new trade routes connecting raw materials with production facilities.

Cultural and Social Legacy

#The first American factory towns established enduring cultural patterns that transformed social norms and labor relations in 19th-century America. These industrial communities created lasting legacies in women's rights, labor reform and educational advancement.

Women's Rights and Labor Reform

#Factory towns revolutionized women's role in the American workforce through the employment of "mill girls" in textile production. The Lowell Female Labor Reform Association, founded in 1844, became America's first organization of working women, publishing "The Factory Tracts" to expose workplace conditions. Female workers organized strikes in 1834 and 1836, protesting wage cuts and establishing precedents for labor activism. The movement achieved several reforms:

- Reduced working hours from 73 to 68 weekly

- Implementation of workplace safety measures

- Creation of grievance procedures

- Formation of worker savings programs

- Establishment of health benefits

Educational Initiatives

#Factory towns pioneered corporate-sponsored education programs that expanded learning opportunities for industrial workers. The Lowell system established:

| Educational Program | Participation Rate | Annual Budget |

|---|---|---|

| Evening Schools | 75% of workers | $2,500 |

| Library Access | 85% of employees | $1,800 |

| Lecture Series | 400 attendees weekly | $1,200 |

The educational initiatives included:

- Mandatory literacy classes for workers under 18

- Free access to lending libraries with 3,500+ volumes

- Weekly lectures on science literature arts

- Publication of "The Lowell Offering" literary journal

- Evening classes in mathematics grammar composition

The corporate investment in worker education created a model for industrial communities across New England establishing 15 similar programs by 1850.

Key Takeaways

#- America's first planned factory town was established in Waltham, Massachusetts in 1813 by Francis Cabot Lowell and the Boston Manufacturing Company

- Lowell, Massachusetts, founded in 1821, became the first comprehensively planned industrial city, featuring 40 mills, 5.6 miles of power canals, and 46 boarding houses by 1850

- The Lowell System revolutionized manufacturing by combining industrial production with worker housing, education, and social infrastructure, creating a model replicated across New England

- Female workers ("mill girls") were central to early factory towns, working 73-hour weeks and living in supervised boarding houses with access to libraries and educational programs

- Factory towns significantly impacted American industrialization, leading to a 300% increase in manufacturing productivity and the establishment of 24 new industrial communities between 1820-1850

Conclusion

#The establishment of America's first factory towns marked a pivotal moment in the nation's industrial development. Waltham and Lowell Massachusetts set groundbreaking precedents that transformed manufacturing processes and social structures. These innovative communities created a blueprint for industrial development that spread across New England and beyond.

The legacy of these early factory towns extends far beyond their economic impact. They pioneered worker welfare programs established new standards for labor conditions and sparked important social reforms. The revolutionary "Lowell System" not only modernized manufacturing but also laid the foundation for America's industrial future. Today these historic communities stand as testaments to the ingenuity and determination that shaped American industry.