Cyrus McCormick invented the mechanical reaper in 1831, revolutionizing agriculture by significantly reducing manual labor in grain harvesting. This groundbreaking invention increased farming efficiency by 400% and laid the foundation for modern agricultural machinery.

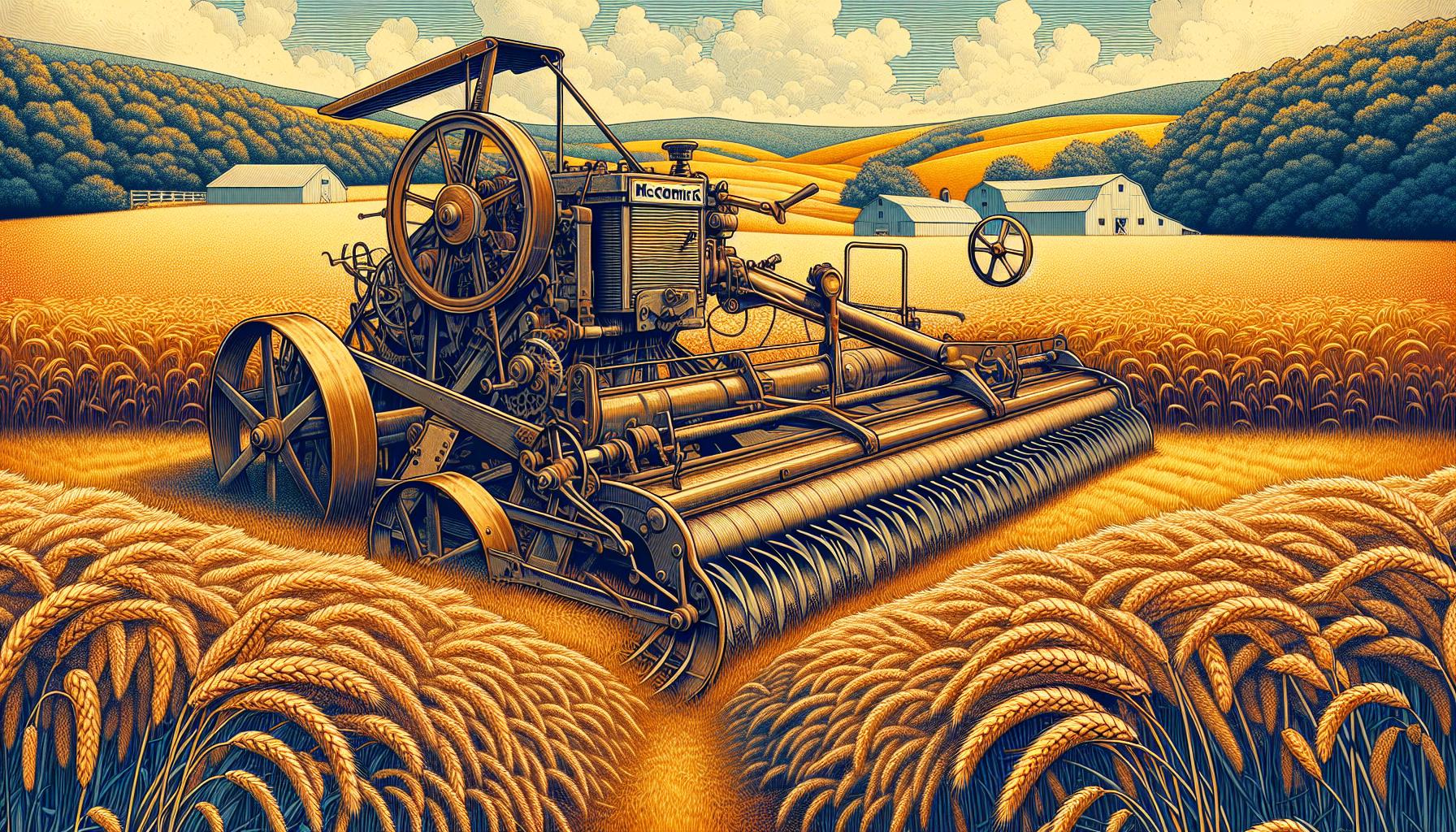

The McCormick Reaper revolutionized agriculture in the 1830s, marking a pivotal moment in farming history. This groundbreaking invention transformed the way farmers harvested their crops and laid the foundation for modern agricultural machinery.

Cyrus McCormick developed his mechanical reaper in 1831 after years of experimentation on his family's farm in Virginia. The invention significantly reduced the manual labor required for harvesting wheat and other grains. What once took a dozen workers several days to accomplish could now be done by just a few people in a fraction of the time. This innovation played a crucial role in America's agricultural expansion and helped establish the country as a global farming powerhouse.

The Birth of the McCormick Reaper in 1831

#Cyrus McCormick invented the mechanical reaper in 1831 at his family's Walnut Grove Farm in Virginia. The breakthrough came after numerous prototypes led to a successful design that cut grain efficiently using a reciprocating knife.

Cyrus McCormick's Early Experiments

#Cyrus McCormick began experimenting with mechanical harvesting designs at age 15 in 1824. His father Robert McCormick's failed attempts at creating a mechanical reaper provided valuable insights for his own design process. Key components of his early prototypes included:

-

A straight reciprocating cutting blade

-

A platform to catch falling grain

-

A revolving reel to push standing grain toward the blade

-

A divider to separate cut from uncut grain

-

Harvesting 2 acres of oats in one afternoon

-

Operating with a single horse pulling the machine

-

Cutting grain at 4x the speed of manual harvesting

-

Maintaining consistent cutting quality across the field

| Demonstration Metrics | Results |

|---|---|

| Area Harvested | 2 acres |

| Time Required | 1 afternoon |

| Horses Needed | 1 |

| Speed Increase | 400% |

Key Features of the Original McCormick Reaper

#The original McCormick Reaper incorporated innovative mechanical elements that revolutionized grain harvesting in the 19th century. Its design combined efficient cutting technology with practical operational features that set new standards for agricultural machinery.

Revolutionary Cutting Mechanism

#The reaper's cutting system featured a serrated reciprocating blade that moved side-to-side against stationary fingers. This mechanism included:

-

A straight cutting edge spanning 4.5 feet in length

-

Triangular-shaped knife sections mounted on a steel bar

-

Fixed guard fingers that held grain stalks in place during cutting

-

A divider rod that separated standing grain from cut grain

-

A large drive wheel measuring 3 feet in diameter

-

A wooden platform to collect cut grain

-

A seat for the raker positioned behind the cutting bar

-

A series of gears that converted the wheel's rotation into blade movement

-

A single-horse draft system requiring minimal animal power

-

A rear wheel for stability during field operations

| Component | Specification |

|---|---|

| Cutting Width | 4.5 feet |

| Drive Wheel Size | 3 feet diameter |

| Operating Speed | 2-3 mph |

| Daily Coverage | 10-12 acres |

| Crew Required | 2 people |

Impact on American Agriculture

#The McCormick Reaper transformed American agriculture through revolutionary mechanization that increased farm productivity tenfold. This innovation catalyzed significant economic changes across the United States during the 19th century.

Increased Farm Productivity

#The McCormick Reaper dramatically enhanced agricultural output by replacing manual harvesting methods. A single reaper harvested 12 acres per day compared to the 0.5 acres harvested by hand, representing a 2400% increase in productivity. Farmers reduced their required harvest workforce from 5-6 workers per acre to just 2 workers operating the reaper, enabling larger wheat fields cultivation. This mechanization led to expanded farming operations in the Midwest, with wheat acreage increasing from 34,000 acres in 1847 to 2.5 million acres by 1860.

Economic Growth in the 1800s

#The widespread adoption of the McCormick Reaper generated substantial economic benefits across multiple sectors. The manufacturing facility in Chicago produced 4,000 reapers in 1856, creating 120 industrial jobs. Wheat exports rose from 4.3 million bushels in 1840 to 30 million bushels by 1860, establishing America as a global agricultural power. Railroad companies experienced growth through increased grain transportation, with rail lines expanding from 9,000 miles in 1850 to 30,000 miles by 1860. The reaper's impact extended to banking, with agricultural loans increasing 300% between 1850-1870 as farmers invested in mechanization.

| Economic Impact Metrics (1840-1860) | Before Reaper | After Reaper | Growth |

|---|---|---|---|

| Annual Wheat Exports (bushels) | 4.3 million | 30 million | 598% |

| Railroad Network (miles) | 9,000 | 30,000 | 233% |

| Midwest Wheat Acreage | 34,000 | 2.5 million | 7,253% |

| Chicago Reaper Production (units) | 100 (1847) | 4,000 (1856) | 3,900% |

Evolution of the McCormick Reaper

#The McCormick Reaper underwent significant technological advancements from its initial 1831 design through subsequent decades. These improvements enhanced its efficiency and reliability, leading to widespread adoption across American farms.

Design Improvements Over Time

#Cyrus McCormick refined the reaper's design through multiple iterations between 1831-1850. The 1834 model introduced a straight reciprocating knife with triangular sections replacing the original curved sickle. In 1845, McCormick added a reel to hold grain steady and a platform where a raker could work efficiently. The 1847 version featured:

- Automated raking mechanism

- Improved cutting blade with serrated edges

- Adjustable cutting height system

- Enhanced drive wheel traction

- Metal framework replacing wooden components

Formation of McCormick Harvesting Machine Company

#McCormick established his manufacturing operation in Chicago in 1847. Key developments include:

| Year | Achievement | Impact |

|---|---|---|

| 1848 | First factory opened | 500 machines produced annually |

| 1851 | Patent renewal granted | Protected design for 14 years |

| 1856 | Production expansion | 4,000 units manufactured |

| 1859 | New factory complex | Doubled production capacity |

The company standardized production methods through:

- Assembly line manufacturing processes

- Quality control measures

- Interchangeable parts system

- Network of trained mechanics

- Regional sales offices

By 1879, the operation transformed into the McCormick Harvesting Machine Company, producing 50,000 machines annually through a workforce of 800 employees.

Legacy and Modern Influence

#The McCormick Reaper's influence extends far beyond its 19th-century origins, shaping modern agricultural practices and industrial development. The International Harvester Company, formed in 1902 through the merger of McCormick Harvesting Machine Company and Deering Harvester Company, carried forward the reaper's technological legacy.

Agricultural Innovation Impact

#Modern combine harvesters trace their lineage directly to McCormick's invention, incorporating key mechanical principles:

- Automated cutting mechanisms derived from the original reciprocating blade design

- Platform-based collection systems similar to McCormick's grain-catching platform

- Mechanical reel systems that evolved from the initial horse-drawn design

Industrial Manufacturing Effects

#The McCormick Reaper established foundational manufacturing practices that remain relevant:

- Assembly line production methods implemented at the Chicago factory in 1847

- Standardized parts manufacturing for consistent quality control

- Systematic warranty programs protecting customer investments

- Specialized dealer networks for distribution and service

Contemporary Agricultural Equipment

#The reaper's influence appears in current farming technology:

- GPS-guided harvesters using automated cutting heights

- Computer-controlled grain separation systems

- Real-time yield monitoring equipment

- Precision agriculture technologies

| Metric | Original McCormick Reaper (1831) | Modern Combine Harvester |

|---|---|---|

| Daily Harvest Capacity | 12 acres | 200+ acres |

| Operating Speed | 2-3 mph | 5-7 mph |

| Labor Required | 2 workers | 1 operator |

| Grain Loss Rate | 10-15% | 1-2% |

The patent system McCormick utilized to protect his invention established precedents for agricultural machinery patents, with over 5,000 active patents registered for combine harvester improvements between 2000-2020 according to the U.S. Patent Office.

Key Takeaways

#- The McCormick Reaper was invented by Cyrus McCormick in 1831 at his family's Walnut Grove Farm in Virginia, revolutionizing agricultural practices

- The original design increased harvesting efficiency by 400%, allowing 2 workers to harvest up to 12 acres per day compared to traditional manual methods

- Key features included a 4.5-foot serrated reciprocating blade, wooden collection platform, and single-horse operation system

- The invention led to massive agricultural growth, with Midwest wheat acreage expanding from 34,000 acres in 1847 to 2.5 million acres by 1860

- McCormick established his manufacturing company in Chicago in 1847, producing 4,000 reapers annually by 1856

- The reaper's legacy continues today through modern combine harvesters and established foundational manufacturing practices still used in agricultural equipment

Conclusion

#The McCormick Reaper stands as one of history's most transformative agricultural innovations. Its invention in 1831 marked the beginning of modern farming practices revolutionizing grain harvesting and boosting American agricultural productivity to unprecedented levels.

The legacy of Cyrus McCormick's invention continues to influence today's farming technology. From its humble beginnings at Walnut Grove Farm to becoming the foundation of contemporary harvesting equipment the McCormick Reaper's impact on agriculture manufacturing and economic growth remains unmatched. Its principles live on in modern combine harvesters demonstrating the enduring significance of this groundbreaking 19th-century innovation.